Project Overcoat

Team: Garrett Mosiman, PI, Liz Kutschke

Program: Center for Sustainable Building Research

The potential for retrofits resulting in deep energy savings for multifamily residential buildings using a novel exterior upgrade panel system and updated mechanical equipment.

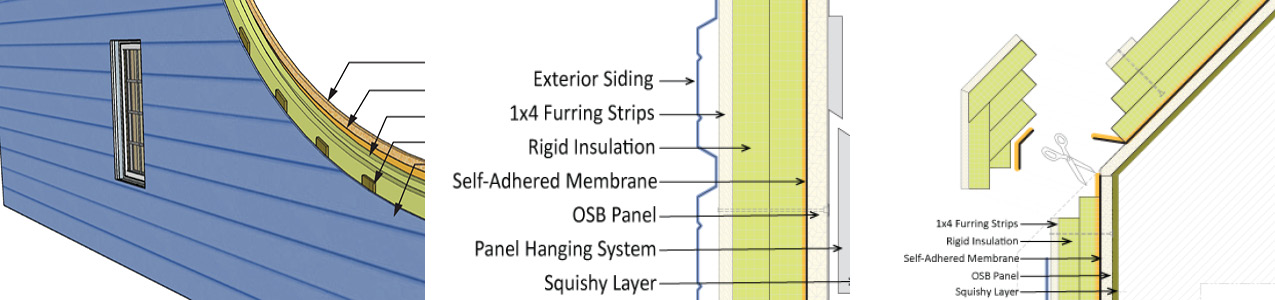

This project explores a novel exterior upgrade derived from work conducted by the NorthernSTAR Building America Partnership that developed and deployed a “studless” exterior wall system. This system uses two layers of large-format oriented strand board as the home’s structural component. Control layers (air, water, vapor, thermal) and finishes are applied to the exterior of this panel. The retrofit strategy presented here eliminates one layer of OSB. A membrane, integrated with fenestrations, is the air / water / vapor control layer. Rigid insulation is the thermal control layer.

The panel is intended to be fabricated offsite, using a technique called EnergieSprong. This concept, developed in the Netherlands before being deployed in the EU and US, uses a 3-dimensional laser scanner to measure the existing building and generate a computer model. This model is then used to guide computer-controlled manufacturing equipment to fabricate the panels. The panels are shipped with fenestration and finishes pre-installed. This allows on-site work to progress rapidly, since the panels are simply mounted to the building’s exterior.

This report describes the proposed panel, its energy and thermal performance, and manufacturing and installation techniques. Mechanical system modifications are also addressed, and a discussion of cost-effectiveness is included.

Funders: Minnesota Department of Commerce, Conservation Applied Research and Development (CARD) Grant